References

ACS-Umwelttechnik has successfully offered wastewater treatment solutions worldwide for many years, in various sizes and industries. Some of the outstanding projects will be presented to you here in the slideshow. Each reference is unique as each project has been individually designed with our customers.

Please contact us if you are interested in the complete list of references, if you would like to visit a reference plant or if you need further information about the plants.

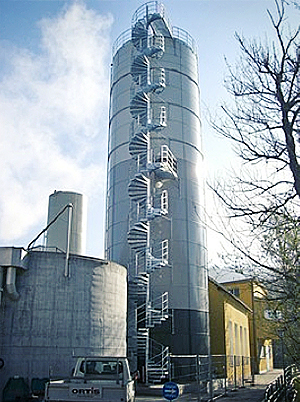

Beverages Lupo

Description:

A high performance EGSB reactor with patented technology at Swiss bottlers. Additional requirements were an aesthetic design as well as an absolutely neutral smell, as the plant is adjacent to a residential area. The main components are pre-acidification in the mixing and equalization tanks, an anaerobic reactor and a secondary aeration tank with secondary clarification.

Substrate:

Wastewater from the production of beer / fruit juice

Calculated for:

650 m³/d, COD 2.500 kg/d

Location:

Hochdorf, Switzlerand

Similar references:

Pyraser Landbrauerei GmbH & Co. KG

Thüringer Fish Delicatessen Gebr.Hopf

Description:

The plant in Thuringia manufactures fish delicatessen, which include ingredients like vinegar and mayonnaise.

The particular requirement of the wastewater treatment was to be able to process both the low pH-values, as well as the oil / fat components. The COD removal efficiency is particularly high (over 90%).

Substrate:

wastewater from production

Calculated for:

40 m³/d, 500 kg COD/d

Location:

Floh-Seligenthal, Germany

Similar references:

Rügen Fisch AG, Unilever UK Ltd, DSF, Lausitzer Früchte

Paper Factory Mondi Frohnleiten

Description:

The ACS EGSB reactor at the paper mill Mondi/Frohnleiten was built without a conditioning tank. An internal circulation and a controlled acidification, made the simplified operation possible. The system is characterized by a robust technology and high process stability. The plant is characteristic for it’s high loading rate and odor-neutrality.

Substrate:

Wastewater from the waste paper processing

Calculated for:

4.000 m3/d, COD 20.000 kg/d

Location:

Frohnleiten, Austria

Similar references:

Klingele Papierwerke, SCA Hygiene Paper GmbH, DS Smith Aschaffenburg

Brewery Leikeim

Description:

A complete system for direct discharge consisting of an EGSB reactor, aeration tank and a final sedimentation. The nitrification / denitrification takes place in an aeration tank. The biogas is used energetically in the boiler house and the exhaust air is cleaned in a biofilter.

Substrate:

Wastewater from the production

Calculated for:

560 m³/d, COD 2.200 kg/d

Location:

Altenkunstadt, Germany

Similar references:

Brauerei Metzler, Pyraser Landbrauerei GmbH & Co. KG

Yeast Factory Leiber GmbH

Description:

An entire plant controlled by a process control system for the yeast factory consisting of: two ACS EGSB reactors, an acidification tank, biogas storage, gas washing unit and biological desulfurization. The biogas is converted into electricity via CHP and used to supply the public network. The wastewater treatment plant is part of the award of the “Energy Efficiency Award” in 2008.

Substrate:

Wastewater from processing of brewer’s yeast

Calculated for:

720 m³/d, COD 10.000 kg/d

Location:

Bramsche, Germany

Similar references:

Alltech Fermin

Rendering SNP Lingen

Description:

The anaerobic wastewater treatment process eliminates the polluting compounds in the wastewater and converts them very efficiently into energy-rich biogas. The methane gas is used by a combined heat and power plant converting it into electricity and heat.

Substrate:

Wastewater from a rendering plant

Calculated for:

4.700 kg/d COD, 341m³ Volume, 800mg/l COd Effluent

Location:

Lingen, Germany

Paper Factory Klingele

Description:

With a high-technology wastewater treatment plant, the wastewater is biologically purified in a two-step process. The organic ingredients of the water are fermented into biogas in the anaerobic reactor. This is converted in a CHP into electricity and heat, which is used in the paper mill.

Substrate:

Wastewater from the waste paper processing

Calculated for:

3.600 m³/d, COD 16.000 kg/d

Standort:

Weener, Germany

Similar references:

Mondi

Yeast Production Alltech-Fermin

Description:

The wastewater from the production process is pre-treated in a central wastewater treatment plant and then passed directly into the river Tisza, a tributary of the Danube. For an energy-efficient treatment of wastewater with a high organic load, an EGSB reactor was used successfully to reduce the organic carbon content.

Substrate:

Wastewater from the yeast production

Calculated for:

COD 60.000 kg/d

Location:

Senta, Serbia

Similar references:

Leiber

Ice cream Unilever

Description:

A high-technology EGSB reactor from ACS replaced an old, costly, aerobic wastewater treatment plant. The anaerobic treatment of wastewater lead to significant savings through reduced energy consumption and a lower production of sludge.

Substrate:

Wastewater from the ice cream production

Calculated for:

800 m3/d, COD 8.000 kg/d

Location:

Gloucester, England

Similar references:

DSF, Nadler Feinkost, Rügen Fisch, Lausitzer Früchte, van Netten Süßwarenfabrik

Papierfabrik SCA Hygiene Paper GmbH

Description:

The high effluent charges could be reduced significantly by using an EGSB reactor. The produced biogas can be converted in a combined heat and power unit to electricity and heat.

Substrate:

Total wastewater from the paper processing

Calculated for:

3.000 m3/d, COD 16.000 kg/d

Location:

Mainz-Kostheim, Germany

Similar references:

Mondi, Klingele Papierwerke