Wastewater treatment of yeast industry

The most important source of raw material in the yeast industry is a byproduct of the sugar industry; molasses. Molasses, in the dry matter, contains 60% fermentable sugar and 40% non-sugar containing substances that cannot essentially be used by yeast.

Substances that cannot be used by the yeast remain in the wastewater and can cause serious pollution to the environment if they are passed into nature without any further treatment. Very high COD concentration values between 15,000 and 50,000 mg/l COD are indicative.

Due to the specific composition of a mixture with very fine yeast particles, a special technology adapted to the operation is required.

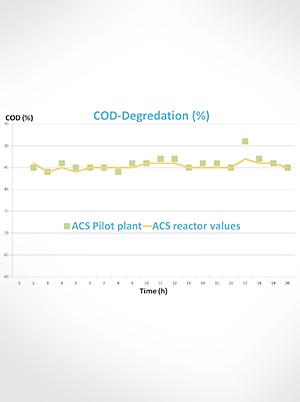

The ACS EGSB reactor, coupled with existing technologies such as flotation and sedimentation, can be used successfully for this application. With its patented technology, the ACS EGSB reactor reduces the COD load by 85-90%. The BOD5 concentrations can also further be reduced by approximately 90%.

Example pant

Yeast Factory Leiber GmbH

| Description |

An entire plant controlled by a process control system for the yeast factory consisting of: two ACS EGSB reactors, an acidification tank, biogas storage, gas washing unit and biological desulfurization. The biogas is converted into electricity via CHP and used to supply the public network. The wastewater treatment plant is part of the award of the “Energy Efficiency Award” in 2008. |

| Substrate | Wastewater from processing of brewer’s yeast |

| Calculated for | 720 m³/d, COD 10.000 kg/d |

| Location | Bramsche, Germany |

| Similar references | Alltech Fermin |