Wastewater treatment of pulp and paper industry

Wastewater from the pulp and paper industry represents, in most cases, a large flow rate with a high proportion of organic degradable substances. The COD values can be found often in the range of 3,500 mg/l up to 6,000 mg/l.

A good separation of fibers and a balance of nutrient ratios are necessary before an anaerobic treatment. Depending on the composition of the wastewater, there are many possible modifications of the reactor.

ACS-Umwelttechnik has successfully built a number of references in the paper industry, even for systems with very high sulfur content or with high lime precipitation.

In recent years, ACS additionally developed a pellet collector, which efficiently prevents a loss of bacteria.

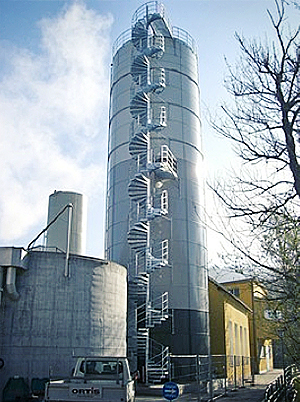

The ACS EGSB reactor, with its patented technology, is particularly suitable for the pulp and paper industry. The reactor reduces the COD by 85-90% and the BOD5 concentration by 90% depending on the type of wastewater. ACS EGSB reactors are used in various plants in line with IC reactors from Paques or Biobed EGSB reactors from Biothane and are available for a direct comparison.

Suitable reactor:

Example pant

Paper Factory Mondi Frohnleiten

| Description | The ACS EGSB reactor at the paper mill Mondi/Frohnleiten was built without a conditioning tank. An internal circulation and a controlled acidification, made the simplified operation possible. The system is characterized by a robust technology and high process stability. The plant is characteristic for it’s high loading rate and odor-neutrality. |

| Substrate | Wastewater from the waste paper processing |

| Calculated for | 4.000 m3/d, COD 20.000 kg/d |

| Location | Frohnleiten, Austria |

| Similar references | Klingele Papierwerke, SCA Hygiene Paper GmbH, DS Smith Aschaffenburg |